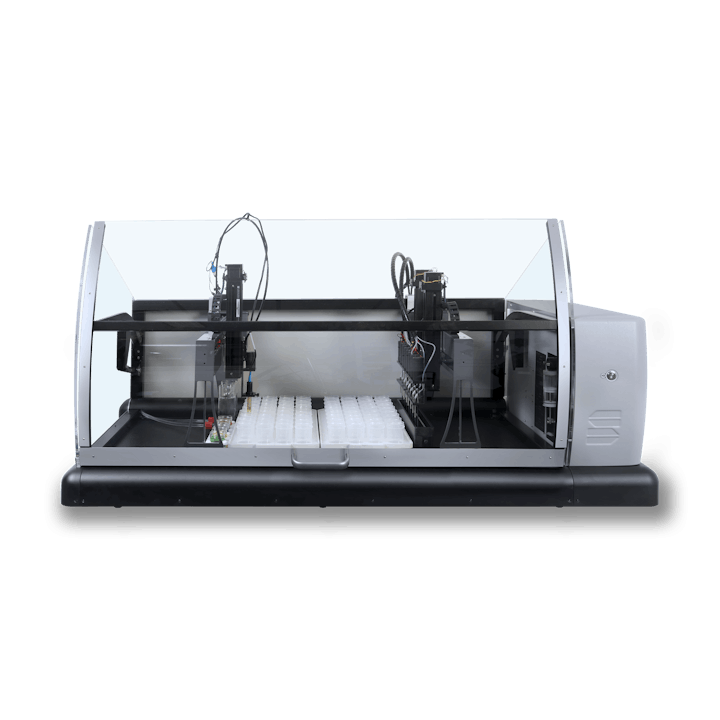

SP2000 Series

Plateformes d'automatisation clés en main ou sur mesure

Les plateformes robotiques sophistiquées SP2000 de Skalar offrent des solutions d'automatisation dédiées et flexibles pour les analyses de routine.

Les analyses de routine n'ont jamais été aussi faciles!

Les solutions d'automatisation SP2000 sont disponibles pour une variété d'applications incluant : DBO, DCO, applications de kits de test, pH, conductivité (EC), alcalinité et autres titrations, turbidité, couleur, applications d'électrodes sélectives d'ions (ISE), granulométrie, pesée automatique, filtration des échantillons, etc. Des combinaisons d'analyses ou des applications sur mesure sont également possibles. Toutes les méthodes appliquées sont conformes aux réglementations internationales NF, ISO, EPA, méthodes standard, DIN, etc.

La conception modulaire et l'automatisation flexible définie par l'utilisateur permettent aux instruments de répondre exactement à vos besoins, ce qui se traduit par une augmentation de la productivité, de la précision de résultats, tout en réduisant le délai d'analyse, les coûts par échantillon et les erreurs d'opération.

La plate-forme complète est protégée par des capots frontaux et latéraux, conformément aux réglementations CE en vigueur. Les analyseurs sont pilotés par notre propre logiciel RoboticAccessTM qui comprend des fichiers d'application prédéfinis, un planificateur d'analyses, une table d'échantillons définissable par l'utilisateur, des options d'impression et d'exportation vers LIMS/Excel personnalisables par l'utilisateur et un ensemble complet de fonctions de contrôle de la qualité.

Les plateformes SP2000 sont évolutives et peuvent être modifiées en fonction de l'évolution de vos besoins, ce qui rend votre investissement initial encore plus précieux.

Analyseurs robotisés SP2000

Les plates-formes SP2000 peuvent être utilisées pour la préparation automatique d'échantillons et/ou l'analyse automatique d'échantillons.

Analyse de la demande biochimique en oxygène (DBO)

L'analyse de la DBO est l'application la plus courante pour les laboratoires d'analyse de l'eau. Ce test est utilisé comme indicateur de la pollution organique de l'eau.

L'analyseur de DBO de Skalar est l'une des plateformes les plus flexibles disponibles aujourd'hui. Outre son design moderne et ses dernières innovations technologiques, il peut être configuré de 18 à 198 bouteilles de DBO. L'analyseur est conçu pour répondre aux exigences exactes de votre laboratoire en ce qui concerne le débit d'échantillons, le niveau d'automatisation, la capacité d'échantillons, etc. Les analyses sont effectuées conformément aux principales réglementations nationales et internationales telles que EPA 405.1/ISO 5815-1/ EN-1899-1/2, Standard Methods 5210 B, DIN 38409, etc. ainsi qu'aux méthodes spécifiques du client.

Qu'est-ce qui peut être automatisé?

- Pipetage de l'échantillon

- Mesure et/ou ajustement du pH de l'échantillon

- Ajout d'un inhibiteur de nitrification (ATU) et/ou d'un ensemencement

- Ajout d'eau de dilution

- Homogénéisation de l'échantillon

- Mesure de la valeur initiale de l'oxygène dissous (DO1)

- Rinçage de la sonde/de l'agitateur entre chaque mesure

- Bouchage/débouchage de la bouteille

- Mesure de la valeur finale de l'oxygène dissous (DO2)

- Calcul de la DBO conformément à la réglementation en vigueur

Si d'autres analyses sont nécessaires, telles que le pH, la conductivité, l'alcalinité, elles peuvent être combinées avec la DBO sur le même robot.

Vous voulez voir comment cela fonctionne ? Cliquez sur le bouton pour regarder notre vidéo de démonstration.

Analyse de la demande chimique en oxygène (DCO)

L'analyse de la DCO est couramment utilisée pour déterminer la quantité de polluants organiques présents dans les eaux de surface et les eaux usées. La valeur de la DCO est un indicateur utile pour mesurer la qualité de l'eau.

DCO (ISO 15705/EPA 410.4)

L'automatisation de cette méthode est basée exactement sur la même réaction que la méthode classique, mais au lieu d'un titrage, une détection photométrique est utilisée. Toutes les étapes de manipulation manuelle sont automatisées. Un avantage est l'utilisation de tubes préparés à l'avance, ce qui minimise la manipulation de réactifs toxiques et dangereux. Les analyseurs peuvent être utilisés avec des tubes de réaction de DCO disponibles dans le commerce ou fabriqués par l'utilisateur et sont compatibles avec plusieurs photomètres.

DCO par titration (NF T90-101 / ISO 6060)

L'analyseur peut être configuré avec 4-6 supports d'échantillons interchangeables, chacun avec 20 positions. Les échantillons peuvent rester dans les mêmes flacons de la digestion à la titration, préservant ainsi l'intégrité de l'échantillon. L'analyseur est équipé d'un titrateur, d'un embout de burette, d'une sonde et d'un agitateur. Pour étendre la gamme sans changer de burette, la plateforme peut être configurée avec deux titrateurs.

Qu'est-ce qui peut être automatisé?

- Préparation de l'échantillon

- Homogénéisation de l'échantillon

- Titration de l'échantillon

- Rinçage de la pointe de la burette entre chaque mesure

- Calcul de la valeur de la DCO

Analyse de test-kit

Les tests photométriques prêts à l'emploi sont utilisés par de nombreux laboratoires d'analyse de l'eau dans le monde entier.

De nombreux fournisseurs proposent ces kits pour de nombreux paramètres importants dans l'analyse de l'eau et des eaux usées, tels que la DCO, le phosphate total, l'azote total, l'ammonium, le nitrite, etc. L'utilisation de ces kits est simple et sûre, mais nécessite encore de nombreuses manipulations manuelles dans la procédure d'analyse, telles que le pipetage de l'échantillon, le (dé)vissage des bouchons de tubes et le transfert des tubes. En particulier lorsque la quantité d'échantillon augmente ou que différents paramètres doivent être analysés.

Qu'est-ce qui peut être automatisé?

- Pipetage de l'échantillon

- (Dé)Vissage du tube d'échantillon

- Homogénéisation de l'échantillon

- Chauffage/refroidissement de l'échantillon

- Ajout de réactifs

- Détection photométrique

L'analyseur peut être configuré avec un deuxième bras robotisé pour augmenter le débit d'échantillons en utilisant une deuxième pince, une aiguille à échantillon et un agitateur ou pour effectuer des tâches supplémentaires. L'application des kits de tests peut être combinée avec la mesure du pH et de la conductivité (EC) pour d'autres procédures automatiques de préparation de l'échantillon avant l'analyse des kits de tests. Avec la valeur de conductivité de l'échantillon, le logiciel peut automatiquement sélectionner la gamme de mesure la plus optimale pour l'analyse de la DCO de l'échantillon. La dilution et l'ajustement du pH de l'échantillon brut avant l'analyse sont également possibles. La qualification de l'échantillon avant l'analyse permet de réaliser d'importantes économies, car elle évite d'utiliser des gammes de mesure incorrectes et donc de gaspiller des réactifs et des consommables pour les kits de test.

L'analyseur peut prendre en charge des kits de test et des photomètres de différents fournisseurs.

Vous voulez voir comment il fonctionne ? Cliquez sur le bouton pour regarder notre vidéo de démonstration.

Conductivité / pH / titrations / turbidité / couleur / analyse à électrodes sélectives d'ions

Le contrôle précis de la qualité de l'eau potable est très important.

Le robot SP2000 offre aux laboratoires d'analyse de l'eau un concept complet "prêt à l'emploi". Les paramètres typiques du contrôle de la qualité de l'eau, tels que l'oxygène dissous, l'alcalinité, le pH, la conductivité, la couleur (UV/VIS), y compris la filtration, la turbidité, peuvent être entièrement automatisés.

Les flacons de collecte d'échantillons peuvent être placés directement sur le robot, évitant ainsi tout transfert manuel d'échantillons. Un lecteur de code-barres intégré lit le code-barres sur le flacon. L'identification de l'échantillon, y compris les paramètres à analyser, devient visible dans la table d'échantillons. Le SP2000 démarre automatiquement l'analyse de cet échantillon en fonction des données indiquées dans la d'échantillons. Les résultats sont directement visibles après l'analyse.

En fonction de l'application, l'étalonnage de l'instrumentation peut être effectué automatiquement pour garantir une performance précise. Des contrôles de qualité et des étalons peuvent être placés entre les échantillons et les sondes peuvent être réétalonnées automatiquement.

Qu'est-ce qui peut être automatisé?

- Lecture du code-barres pour vérifier l'identité de l'échantillon et obtenir les paramètres d'analyse.

- Bouchage et débouchage des flacons

- Filtration de l'échantillon en ligne ou externe via un filtre à bande de papier

- Homogénéisation de l'échantillon

- Rinçage de la sonde, de l'agitateur, de l'aiguille de prélèvement, des filtres et des cellules en ligne

- Étalonnage de l'instrumentation

- Calcul des résultats

Un double titrateur peut être inclus pour un débit d'échantillons plus élevé et un filtre à bande de papier peut être intégré, permettant l'analyse d'échantillons d'eau chargés de particules. L'analyseur est compatible avec de nombreux modèles actuels d'appareils de mesure et de sondes de divers fabricants. Cette configuration est extensible au fluorure, à la dureté et à de nombreux autres paramètres.

Vous voulez voir comment il fonctionne ? Cliquez sur le bouton pour regarder notre vidéo de démonstration.

pH du sol

La valeur du pH du sol nous donne des informations sur la manière d'améliorer la qualité du sol, ce qui se traduit par une augmentation des quantités cultivées et une réduction des coûts.

L'analyseur SP2000 traite facilement de grandes quantités d'échantillons de sol chaque jour. Le système ajoute l'agent d'extraction requis à l'échantillon, l'agite, attend un temps prédéfini et détermine le pH automatiquement. Toutes les variables de ces étapes, telles que le temps de pré-mélange et les critères de stabilisation, peuvent être adaptées à tout moment pour répondre à tous les types d'échantillons et à toutes les normes en un seul passage.

Qu'est-ce qui peut être automatisé?

- Ajout de la solution d'extraction

- Homogénéisation de l'échantillon

- Mesure du pH

- Etalonnage et rinçage de la sonde

L'analyseur peut contenir jusqu'à 792 récipients (50 ml). Pour les lots extrêmement importants, l'analyseur peut être configuré avec deux bras robotisés ayant chacun plusieurs configurations d'électrodes, jusqu'à un total de 12 électrodes, pour augmenter le débit. Outre l'analyse du pH dans le sol, l'analyseur peut également être étendu à la mesure simultanée de la conductivité électrique (EC).

Vous voulez voir comment il fonctionne ? Cliquez sur le bouton pour regarder notre vidéo de démonstration.

Analyse de la granulométrie

La classification des sols est importante pour le contrôle de l'environnement et la construction.

La classification des sols est basée sur plusieurs facteurs tels que l'absorption, la capacité à se rétracter ou à gonfler, la rétention d'eau et la perméabilité. La plupart de ces facteurs sont indépendamment liés à la taille des particules du sol. La fraction argileuse, la plus petite fraction (0-2 microns), est indispensable pour évaluer la qualité du sol. La fraction argileuse est mesurée conformément à la norme NF X31-107 (ISO 11277), par exemple, et permet de classer le sol dans des catégories déterminées.

L'analyse s'effectue en trois étapes :

- Pesée de l'échantillon et séparation des fractions

- Élimination de la matière organique et des carbonates

- Détermination de la fraction argileuse

Skalar a développé un concept pour automatiser les deuxième et troisième étapes de ce processus. L'automatisation de ces étapes est particulièrement intéressante car elles peuvent désormais être réalisées de manière entièrement automatique, avec un temps et des hauteurs de prélèvement précis. L'élimination de la matière organique et des carbonates est automatisé grâce à l'analyseur robotique SP50. Avec la plateforme SP2000, la détermination de la fraction argileuse est automatisée.

Qu'est-ce qui peut être automatisé?

Le robot de préparation d'échantillons SP50

Le robot de fractionnement d'argile SP2000

- Ajout d'eau

- Chauffage de l'échantillon

- Ajout de peroxyde d'hydrogène

- Refroidissement de l'échantillon

- Ajout d'acide chlorhydrique

- Rinçage de l'échantillon

- Ajout d'une solution de pyrophosphate de sodium

- Ajout d'eau

- Homogénéisation de l'échantillon

- Prélèvement de l'échantillon et transfert dans les récipients d'évaporation

- Correction de la température pour les profondeurs de prélèvement de l'échantillon

- Chauffage de l'échantillon

Le SP2000 peut être configuré avec 35-105 positions pour les allonges de sédimentation (1000 ml) et 35-105 positions pour les coupelles de séchage. Cette procédure peut également être effectuée sans surveillance, ce qui permet un fonctionnement de nuit. De plus, il est également possible de déterminer d'autres fractions.

Solutions pour la préparation des échantillons

L'automatisation de la préparation des échantillons permet non seulement d'accélérer les procédures de laboratoire, mais aussi de gagner un temps précieux et d'augmenter considérablement la précision, la reproductibilité et la productivité.

La plateforme SP2000 est idéale pour automatiser les procédures de préparation des échantillons de manière efficace et précise. Les techniques de préparation des échantillons telles que la distribution, le lavage, la dilution, la filtration, l'ajout de réactifs, la conservation, le mélange, l'homogénéisation, l'ajustement du pH de l'échantillon brut, le chauffage et le refroidissement de l'échantillon peuvent être intégrées. Le robot est compatible avec la plupart des flacons d'échantillons, des flacons de réactifs, des portoirs et peut être équipé de plusieurs aiguilles de pipetage, d'agitateurs et d'homogénéisateurs. Différents dispositifs de (dé)bouchage pour flacons, tubes, bouteilles en plastique avec bouchons à vis, les bouteilles en verre avec bouchons et les récipients avec couvercles magnétiques sont disponibles.

Quelques exemples de configuration:

Le SP2000 peut effectuer les étapes de pesées nécessaires pour la "Matière Volatile en Suspension" (MVS). La perte au feu est utilisée pour fournir une indication de la teneur organique d'un échantillon en contrôlant le changement de poids après avoir été chauffé à haute température (jusqu'à 550°C en différé dans les supports à résistants à la chaleur conçus par Skalar), où l'échantillon perd une partie de son contenu en étant brûlé ou volatilisé. Ces supports sont directement transférables entre le four et le robot. Les applications comprennent la détermination de la teneur en matière organique dans des matériaux tels que les sédiments, les boues, les sols et les déchets, ainsi que des applications industrielles pour le même paramètre dans le ciment, la chaux et la bauxite.

Le robot de pesées a été conçu pour répondre à vos besoins en matière d'analyse des Matières en Suspension Totales (MES). L'analyse des MES est une analyse standard dans l'industrie des eaux usées, car les résultats de l'analyse des MES sont utilisés pour évaluer la performance des processus conventionnels de traitement des déchets et la qualité de l'eau. Cette application automatise complètement le processus de pesées qui prend du temps, permettant à vos analystes de se concentrer sur d'autres tâches. De plus, cette automatisation signifie que les heures de travail conventionnelles d'un laboratoire peuvent être considérablement allongées.

Dans cet exemple d'automatisation avec notre plateforme SP2000, le débouchage, le capsulage et le sertissage des bouchons sur les flacons ainsi que l'ajout de la solution d'extraction et de l'étalon interne sont automatisés.

Un mécanisme d'espacement linéaire peut être intégré à notre plate-forme robotique SP2000, qui est parfaite pour un certain nombre d'applications de préparation d'échantillons. Ce mécanisme pourrait faire gagner du temps à votre laboratoire, tout en assurant l'uniformité grâce à un pipetage précis et cohérent. Plusieurs aiguilles de prélèvement peuvent être montées sur ce mécanisme pour prélever des échantillons dans les flacons d'origine et les distribuer dans des tubes/flacons d'analyse de différentes tailles. La possibilité de passer de grands à petits récipients sur une seule plate-forme permet de réduire considérablement l'encombrement. Des aiguilles supplémentaires pour la dilution simultanée des échantillons et/ou le dosage de réactifs supplémentaires nécessaires à l'analyse peuvent être combinées sur ce même mécanisme d'espacement linéaire.

Avec la mise en œuvre de la procédure de préparation des échantillons pour l'analyse ultérieure des échantillons d'halogénures organiques adsorbables (AOX), le robot prend en charge les étapes manuelles fastidieuses et souvent répétitives, où le temps est compté, telles que le pipetage des échantillons, la dilution, le mélange à différentes vitesses, le (dé)bouchage des flacons d'échantillons, l'ajout de réactifs dangereux tels que les acides et, enfin, la distribution des échantillons dilués à un taux précis de 3 ml/min sur des cartouches dédiées, dans le cadre de la procédure d'extraction pour l'analyse ultérieure des AOX.

Le SP2000 offre une automatisation complète de l'ajout de la solution d'extraction, de l'agitation et de la filtration des échantillons de tabac.

Le robot mesure d'abord la valeur de conductivité (EC) et le pH d'un échantillon filtré et centrifugé. Sur la base de la valeur EC de l'échantillon, le logiciel du robot peut sélectionner automatiquement le facteur de dilution requis pour l'analyse ultérieure des métaux. L'échantillon est prélevé, dilué et distribué dans le portoir pour l'analyse des métaux. Ensuite, l'échantillon non dilué restant est distribué dans différents flacons pour la mesure du carbone organique dissous (COD), le phénol, le cyanure et l'analyse des anions sur d'autres analyseurs.

La procédure de préparation de l'échantillon comporte de nombreuses étapes de manipulation manuelle et peut être assez dangereuse, en raison du dégagement de gaz pendant l'analyse, ainsi que du risque potentiel de contamination du laboratoire par le mercure. C'est pourquoi l'unité complète est placée dans une hotte et équipée d'un extracteur de fumées spécial pour extraire les gaz dangereux sur place.

Logiciel

RoboticAccess est conçu comme un programme flexible et multitâche pour contrôler les analyseurs robotisés Skalar. Pendant l'analyse des échantillons, les résultats déjà obtenus sont traités et de nouvelles analyses peuvent être préparées et programmées. Un code d'accès et un mot de passe sont requis avant l'opération afin d'empêcher toute opération non autorisée et toute modification des données.

Les fichiers d'application, qui contiennent les instructions permettant aux analyseurs d'exécuter les spécifications, sont prédéfinis dans le logiciel par Skalar, conformément aux réglementations (inter)nationales ou peuvent être conformes aux exigences définies par l'utilisateur.

Les analyses peuvent être facilement lancées en sélectionnant l'application requise et en créant simplement une table d'échantillons définie par l'utilisateur en faisant glisser les portoirs vers l'analyseur. Lorsque le tableau d'échantillons est complété et que la séquence d'analyse est définie, l'analyse peut être lancée ou programmée pour une autre heure de démarrage.

Toutes les applications peuvent être programmées pour être analysées. L'état de l'analyse en cours peut être suivi sur l'écran et les résultats sont affichés en temps réel. Pendant l'analyse, il est possible d'ajouter des échantillons prioritaires ou d'exclure des échantillons de la mesure.

Les résultats peuvent être imprimés dans des rapports définis par l'utilisateur et exportés vers un fichier txt, Excel ou LIMS. Les séries terminées peuvent être archivées, sauvegardées et restaurées ultérieurement.

Les fonctions intégrées de contrôle de la qualité garantissent des résultats précis et une conformité totale avec les réglementations en vigueur. Les échantillons de contrôle de qualité peuvent être analysés et des graphiques de contrôle de qualité ainsi que d'autres informations statistiques précieuses peuvent être créés. Des protocoles CLP peuvent également être inclus, ce qui permet à l'analyseur Robot d'agir automatiquement en cas de dépassement des limites de contrôle de la qualité et des limites CLP. Cela garantit la production de résultats très précis et un contrôle qualité automatique des performances de l'analyseur robotisé.

Industries où nous intervenons

Il y a bien sûr d'autres secteurs que nous pouvons servir, mais nous ne les avons pas encore tous répertoriés.